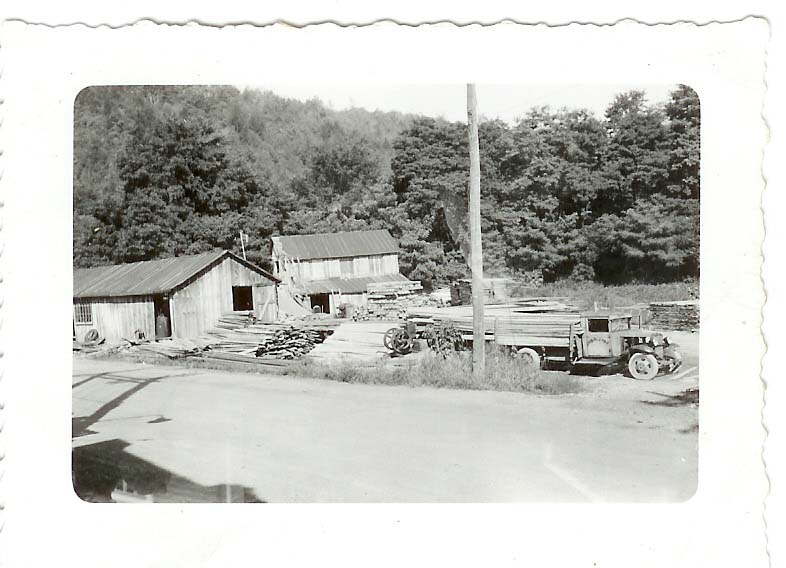

Second sawmill constructed on the Johnston St. site

After working several years as a barber in the shop at the Park View Hotel in New Milford, Clark Howell began a new career. Purchasing slab cut lumber from a local sawmill, Clark would truck the lumber to Scranton to be used as "props" in the coal mines. Mine props were temporary beams used in the coal mining business to support the shafts while being dug. On the return trip, he would bring a truck-load of coal to Binghamton for resale by local coal companies.

Sometime around 1937, Clark purchased the sawmill on Johnston St. because they were unable to produce enough "props" to meet the demand. A short while later, on March 18, 1939, the mill was completely destroyed by fire. The newspaper accounts of the fire stated that the cause was undetermined, although later investigation found a gasoline engine had exploded. The sawmill resumed operation a few days later with an outdoor setup which lasted until a new mill could be built.

Second sawmill constructed on the

Johnston St. site

The second sawmill lasted only a few

years. In the early morning of Thursday September

4, 1941 it was destroyed again. This time due

to sparks from the boiler.

The dumptruck at left was

used to deliver firewood to local patrons. Men in the photo are (l

to r): Raymond Whitney, Earl Ames, Clark Howell, Theodore Tingley,

Lee Wellman.

Herman "Ham" Glatzel and Lee

Wellman

Aerial photo of final sawmill -

Spring 1971

The pallet business continued to grow and it soon became more efficient to purchase hardwood rather than logging and sawing it locally. Reaching the business's peak in the 1950's and 1960's, a unique method of loading the pallets was adopted. Orders shipped via truck to New York City could not be completely loaded at the mill due to the low underpass of the railroad. So the trailer was loaded half way at the sawmill dock and then moved to the side of Johnston St. just east of the culvert. Then a stake bodied truck was used to carry the remainder of the order to finish loading the tractor-trailer for the trip to the City.

The number of employees varied from 10 to 25, depending on business needs. The process of creating pallets began with a truck-load of green (unseasoned) hardwood delivered to the yard and stacked in piles near the railroad tracks. A forklift truck would then bring a stack around to the planer room for smoothing. Each board was passed through the 36" planer to smooth and size them after which they would be re-stacked on a dolly cart to be transported to one of the cut-off stations. At this point the boards were cut to length depending on the requirements of the particular order. Some of the sized boards were then taken to the chamfer room to have edges beveled for easier entry of fork-lifts on the finished product. Next the chamfered boards would meet up with the straight ones and were placed within easy reach of the several pallet tables. A worker would then assemble the pieces, hammering each nail by hand. During the early 1970's, manual nailing of pallets was replaced by more efficient air-nailers.

Clark retired in 1976 and sold the mill. The new owners did not continue the pallet business and after changing hands, the mill was finally razed. Today (2010) only three cinderblock buildings remain.

C. W. Howell II